In the intricate world of supply chain management, the often-overlooked realm of reverse logistics plays a pivotal role. Returns, refurbishments, and recycling are critical components that can impact both a business’s bottom line and its environmental footprint. Let us unveil the transformative role of smart lockers in reverse logistics and the benefits they offer. These intelligent storage solutions are redefining the process of returns and exchanges, streamlining operations, and providing a seamless return experience.

Let’s delve into how smart lockers are rewriting the reverse logistics services, ushering in a new era of efficiency and customer convenience.

Introduction

The logistics sector’s continuous evolution has evolved the concept of reverse logistics and its services. In this fast-paced era, where supply chain management is a symphony of moving parts, the role of smart lockers emerges as a game-changer.

Picture this: an open locker network that’s ready to redefine the entire reverse logistics landscape. With the power to streamline operations, offer 24/7 accessibility, and infuse a fresh wave of convenience for customers, smart lockers are more than just storage units – they’re the catalysts for a seamless return process.

What is Reverse Logistics?

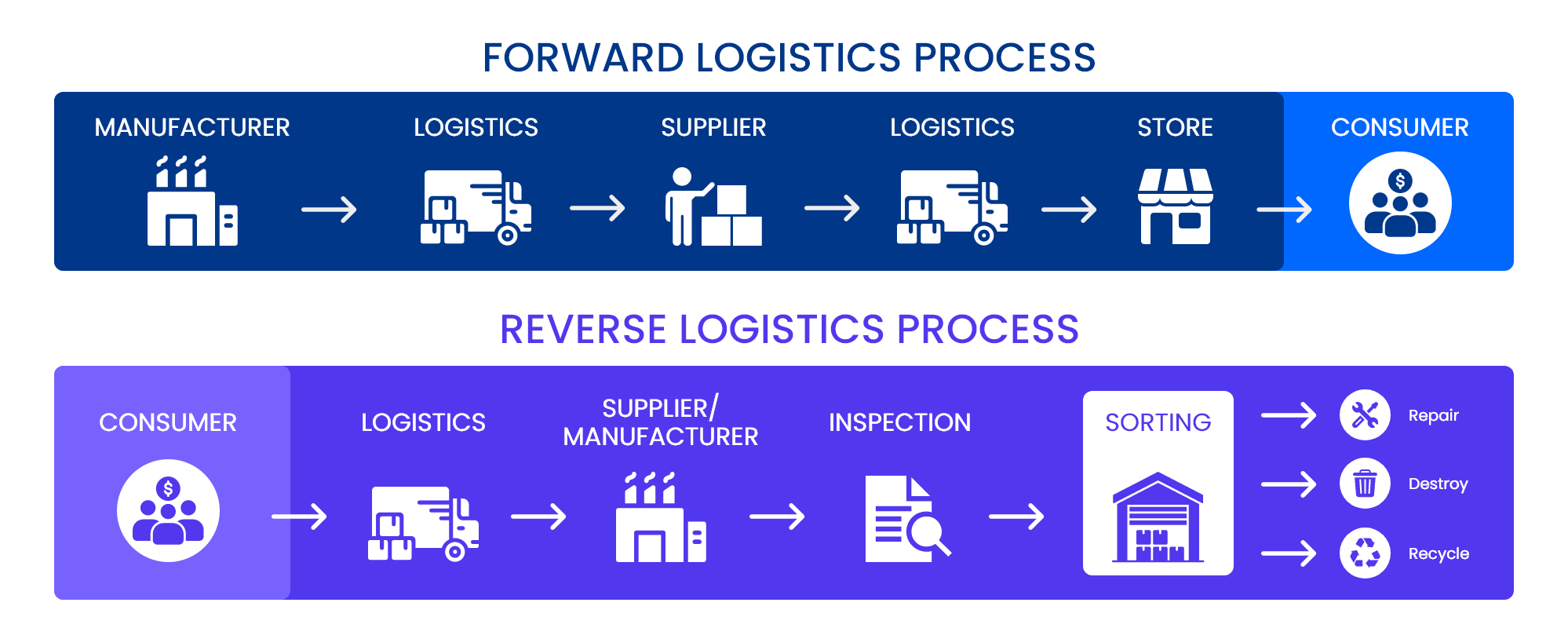

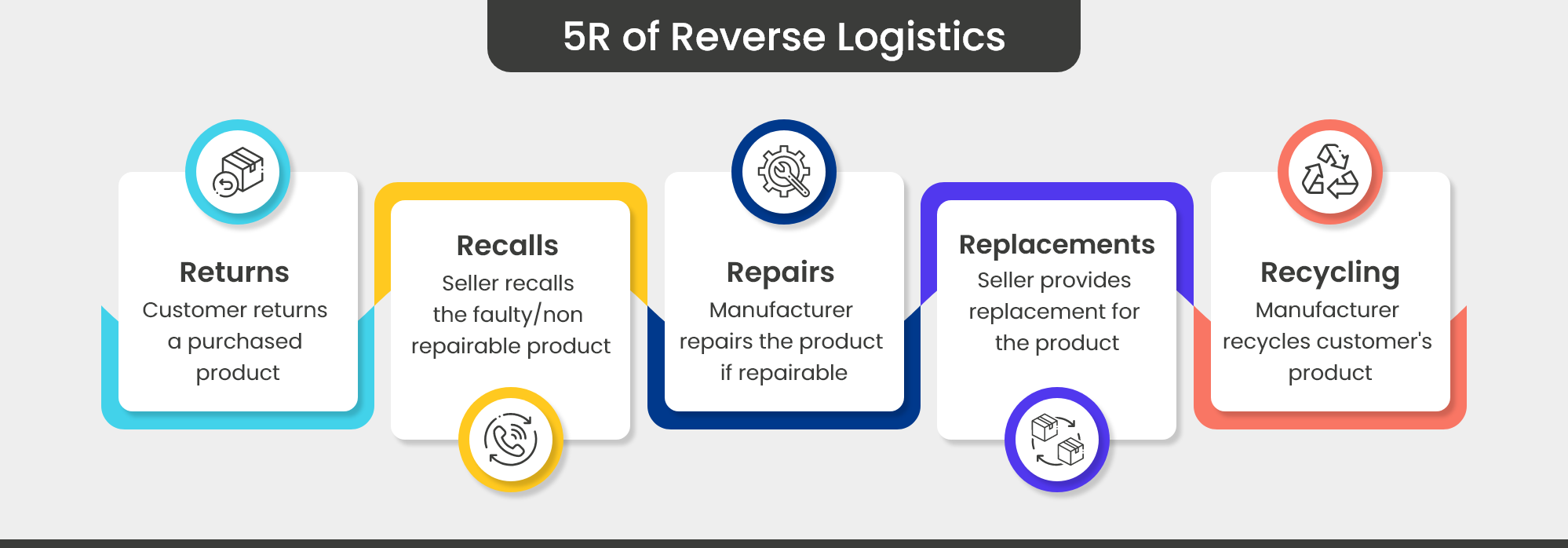

Reverse logistics is the process of handling the movement of goods from the consumer back to the manufacturer or distributor. It encompasses a wide spectrum of activities, including returns, refurbishments, recalls, recycling, and even the disposal of products. While it might sound like the less glamorous side of logistics, reverse logistics holds immense importance in the grand tapestry of supply chain management.

Importance of Reverse Logistics

In today’s business landscape, where customer experience and sustainability are paramount, reverse logistics has taken on a new level of significance. Coherent reverse logistics services result in improved customer satisfaction, ensuring hassle-free returns and exchanges. At the same time, businesses are recognizing the importance of responsible disposal and recycling of products to reduce waste and minimize environmental impact.

“Reverse logistics services not only ask for managing returns, but it also asks for doing so efficiently.”

Inefficient reverse logistics services can lead to additional costs, delays in processing returns, and even damage to a company’s reputation. This is where strategies like utilizing smart lockers are introduced to transform the process by providing streamlined, secure, and convenient solutions for return management.

The Process of Reverse Logistics

In the multi-layered process of reverse logistics, goods flow from producer to consumer and consumer to producer. This process calls for accuracy and extensive tracking making it more than just a backward step; it’s a critical process that holds the key to efficiency, customer satisfaction, and sustainability.

Here are the steps of the Reverse Logistics Process:

- Return Initiation: The reverse logistics journey often starts with a return initiation. This can be prompted by various factors – a dissatisfied customer, a damaged product, or an excess inventory. Regardless of the reason, this step marks the beginning of a process that involves careful assessment and decision-making.

- Product Collection: Once a return is initiated, the product needs to find its way back to the seller or manufacturer. This step involves coordinating the collection of the returned items from the customer’s location, a retail store, or a designated drop-off point.

- Assessment and Sorting: Once returned, the products undergo assessment to determine their condition. Depending on their state, products might be categorized for different paths – repair, refurbishment, recycling, or disposal.

- Repair and Refurbishment: Products that can be repaired or refurbished enter this phase. Skilled technicians assess the damage, make necessary repairs, and ensure that the product is restored to a sellable condition.

- Recycling and Disposal: Products that are beyond repair or refurbishment are often directed toward recycling or responsible disposal. This step is crucial for minimizing waste and adhering to sustainability goals.

- Inventory Management: Returned products often need to be reintegrated into the inventory. This involves updating stock levels, accounting for any changes in product condition, and ensuring the accuracy of inventory records.

- Customer Communication: Clear and effective communication with the customer is essential throughout the process. Customers need to be informed about the status of their return, any repairs made, and the steps taken toward resolution.

Transforming the Reverse Logistics Landscape with Smart Lockers

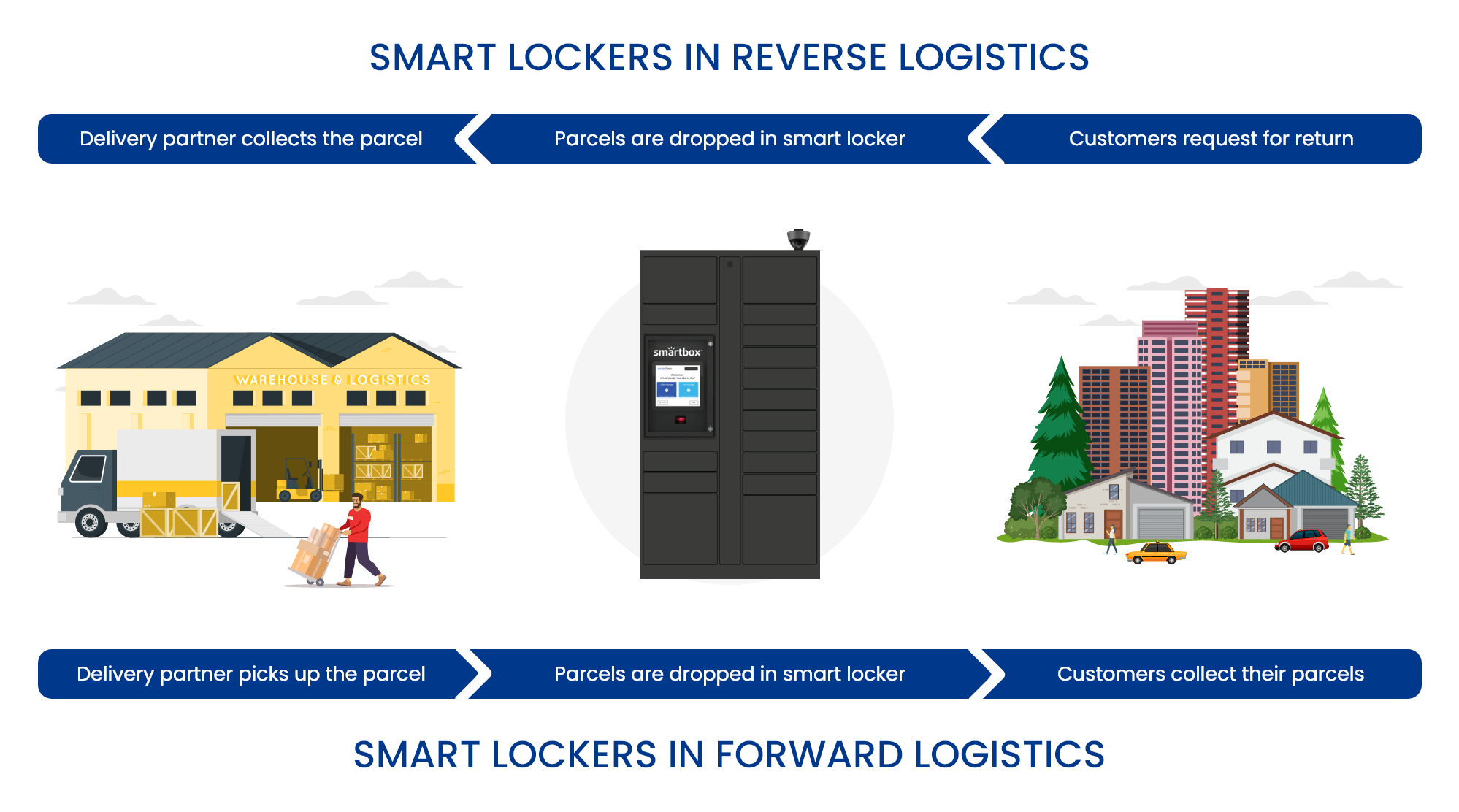

In the domain of reverse logistics, smart lockers have emerged as a groundbreaking solution. These lockers offer a centralized hub for returns, enhancing efficiency, security, and customer convenience. These unassuming automated locker systems are wielding a significant impact, revolutionizing the traditional approach to reverse logistics and ushering in an era of streamlined operations and enhanced customer experiences.

These automated lockers for logistics are a part of an open locker network, available 24/7, and offering a seamless process for customers to return items at their convenience. With the ability to handle multi-channel returns and optimize space utilization, smart lockers are rewriting the rules of reverse logistics services.

Benefits of Smart Lockers in Reverse Logistics

Smart lockers aren’t just storage units; they’re gateways to an efficient, customer-centric, and sustainable future of reverse logistics services. They’re the embodiment of operational innovation, making the complex appear beautifully simple. As businesses embrace this evolution, they embrace a new era of returns – one where convenience, cost savings, and customer satisfaction go hand in hand. To prove this, here are some of the most 5 impactful advantages of smart lockers in reverse logistics:

Navigating Complexity

Smart lockers, with their streamlined approach, untangle the knots of complexities of reverse logistics services. They don’t just store parcels; they streamline the entire process. Imagine a centralized hub that’s accessible round the clock. No more rushing to meet tight deadlines or fitting returns into a limited window. Customers enjoy the freedom to return items when it suits them best, creating a level of convenience that’s both refreshing and satisfying.

The Omni-Channel Advantage

Shopping today isn’t confined to a single channel. Customers dance between online and offline, and smart lockers are in step with this rhythm. They embrace the era of multi-channel returns, making the process uniform and seamless. Whether a purchase was made online or at a brick-and-mortar store, the return process remains consistent. The result? Streamlined retail returns that simplify your logistics equation.

Convenience Beyond Business Hours

In a world where business hours are as diverse as customer preferences, offering 24/7 accessibility is a blessing for customers. They are no longer confined by time restrictions; they can return items on their terms. It’s the epitome of customer-centricity – meeting customers where they are and offering convenience that resonates.

Efficiency and Savings

The magic of smart lockers doesn’t stop at convenience; it extends to the world of cost savings. Think about it – every efficient operation is a cost-efficient operation. These lockers are space optimization wizards. With their compact design, they optimize space, saving you the headache of managing extensive storage facilities. And the reduction in manual handling? That translates to reduced reverse logistics time, faster processing, and, in the end, happier customers.

Security and Sustainability

When parcels are involved, security is paramount. Smart lockers stand tall in offering a secure haven for returned items, ensuring they’re protected until they’re ready for processing. This not only shields your products but also builds trust among your customers. And let’s not forget about sustainability. By optimizing processes and reducing the carbon footprint linked with reverse logistics, these lockers are silent advocates for sustainability.

Conclusion: Embrace the Future of Reverse Logistics with Smart Lockers

The landscape of reverse logistics services is undergoing a great makeover, and at the heart of this transformation are smart lockers. They’re rewriting the rules of the game by simplifying returns and exchanges, fueled by advanced technology. The benefits are clear: streamlined operations, efficient processing, improved customer satisfaction, and a reduced environmental footprint. Smart lockers are more than storage units; they’re catalysts for change in a sector that’s often marked by complexity.

As businesses continue to embrace the efficiency, security, and sustainability offered by smart lockers, they’re stepping into a new era of reverse logistics, where the journey of returns becomes as smooth as the click of a button.

If you’re looking to transform your logistics operations, it’s about time you invited own-branded smart lockers into your operations.

Don't forget to share this post!